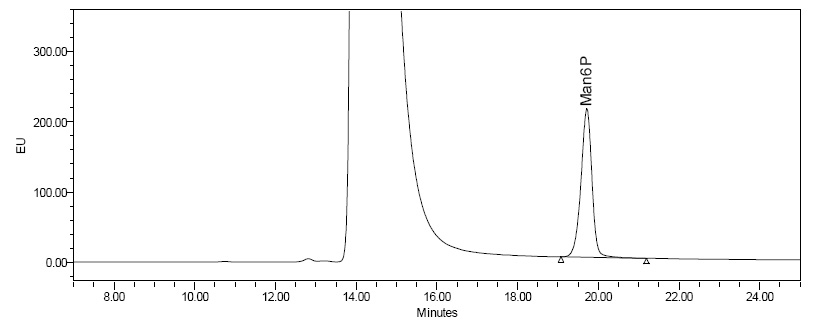

Mannose 6 phosphate quantitative standard

Mannose-6-Phosphate standard, 10nmol (CM-MAN6P-10), which is a quantified monosaccharide reference standard and has been validated using quantitative NMR. We recommend using this standard to assess the Man6P content while characterising your recombinant therapeutic glycoproteins.

Product Specification

Many

therapeutic glycoproteins contain negatively charged glycans such as

sialylated, sulphated and phosphorylated glycans that impact their

structure, function, safety, and efficacy. Therefore, it is a regulatory

requirement to analyse the Glycosylation Critical Quality Attributes (GCQA) of

these drugs.

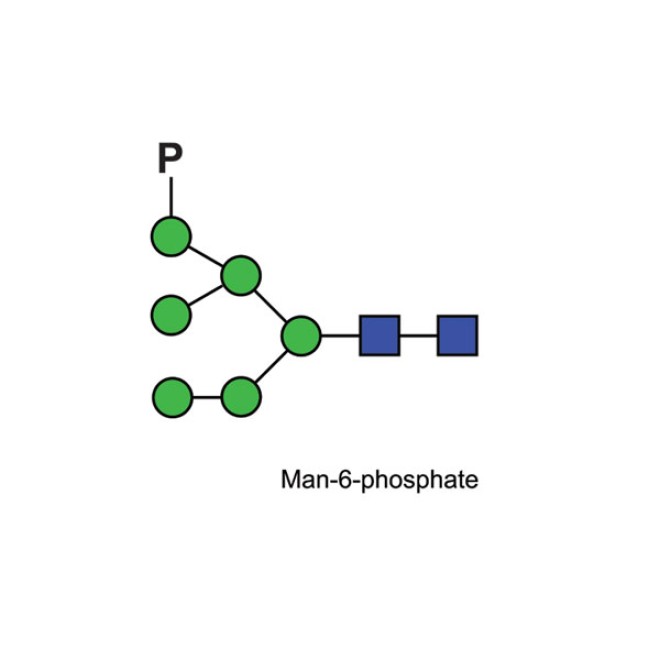

For instance,

Mannose-6-Phosphate (Man6P), a terminal monosaccharide of

asparagine-linked oligosaccharides is a key targeting signal for acid hydrolase

precursor proteins that are destined for transport to lysosomes and is present

in therapeutic enzymes (enzyme replacement therapies) developed for the treatment of lysosomal storage diseases.

This Mannose-6-Phosphate reference

standard (CM-MAN6P-10), which is a quantified monosaccharide has

been validated using quantitative NMR. We recommend using this standard to

assess the Man6P content while characterising your recombinant therapeutic

glycoproteins.

Form: Dry. Dried by centrifugal evaporation from an aqueous solution.

Amount: 10 nmol

Storage: -20˚C both before and after dissolution. This product is stable for at least 5 years as supplied.

Shipping: Shipped at ambient when dry. After dissolution, ship on dry ice.

Handling: Allow the unopened vial to reach ambient temperature and tap unopened on a solid surface to ensure that most of the lyophilized material is at the bottom of the vial. Gently remove the cap, add the desired volume of reconstitution medium, re-cap and mix thoroughly to bring all the oligosaccharides into the solution. For maximal recovery of oligosaccharide, ensure that the cap lining is also rinsed and centrifuge the reconstituted vial briefly before use. Ensure that any glass, plasticware or solvents used are free of glycosidases and environmental carbohydrates—Minimise exposure to elevated temperatures or extremes of pH. High temperatures and low pH will cause desialylation. High pH will cause epimerisation of the reducing terminus GlcNAc.

Safety: This product is non-hazardous and has been purified from natural sources certified to be free of all hazardous material including pathogenic biological agents.

-660x660.jpg)