Sialic acid reference panel

References:

Fernandes, D. Biopharmaceutical Sialylation. European Biopharmaceutical Review. Spring 2006. pp 100 -104

Bhide GP, Colley KJ. Sialylation of N-glycans: mechanism, cellular compartmentalization and function. Histochem Cell Biol. 2017 Feb;147(2):149-174. doi: 10.1007/s00418-016-1520-x. Epub 2016 Dec 14.

Anumula KR. Rapid quantitative determination of sialic acids in glycoproteins by high-performance liquid chromatography with a sensitive fluorescence detection. Analytical Biochemistry 230: pp24-30, 1995,

CM-SRP-01 panel is a standalone product as well as a component in the LudgerTag DMB sialic acid release and labelling kit (LT-KDMB-A1). This kit and the panel can assist you in performing sialic acid analysis which is a regulatory requirement to monitor the level and types of sialic acids during all stages of biopharmaceutical realisation.

Amount: approx. 1.25 nmols

View product documentation

Sialylation Guide I: Neu5Ac and Neu5Gc Quantitation

Sialylation Guide I: Neu5Ac and Neu5Gc Quantitation

Sialylation Guide II: Highly Sialylated Glycoproteins

Sialylation Guide II: Highly Sialylated Glycoproteins

Application Note: Quantitative Sialic Acid Analysis

Application Note: Quantitative Sialic Acid Analysis

Product Specifications

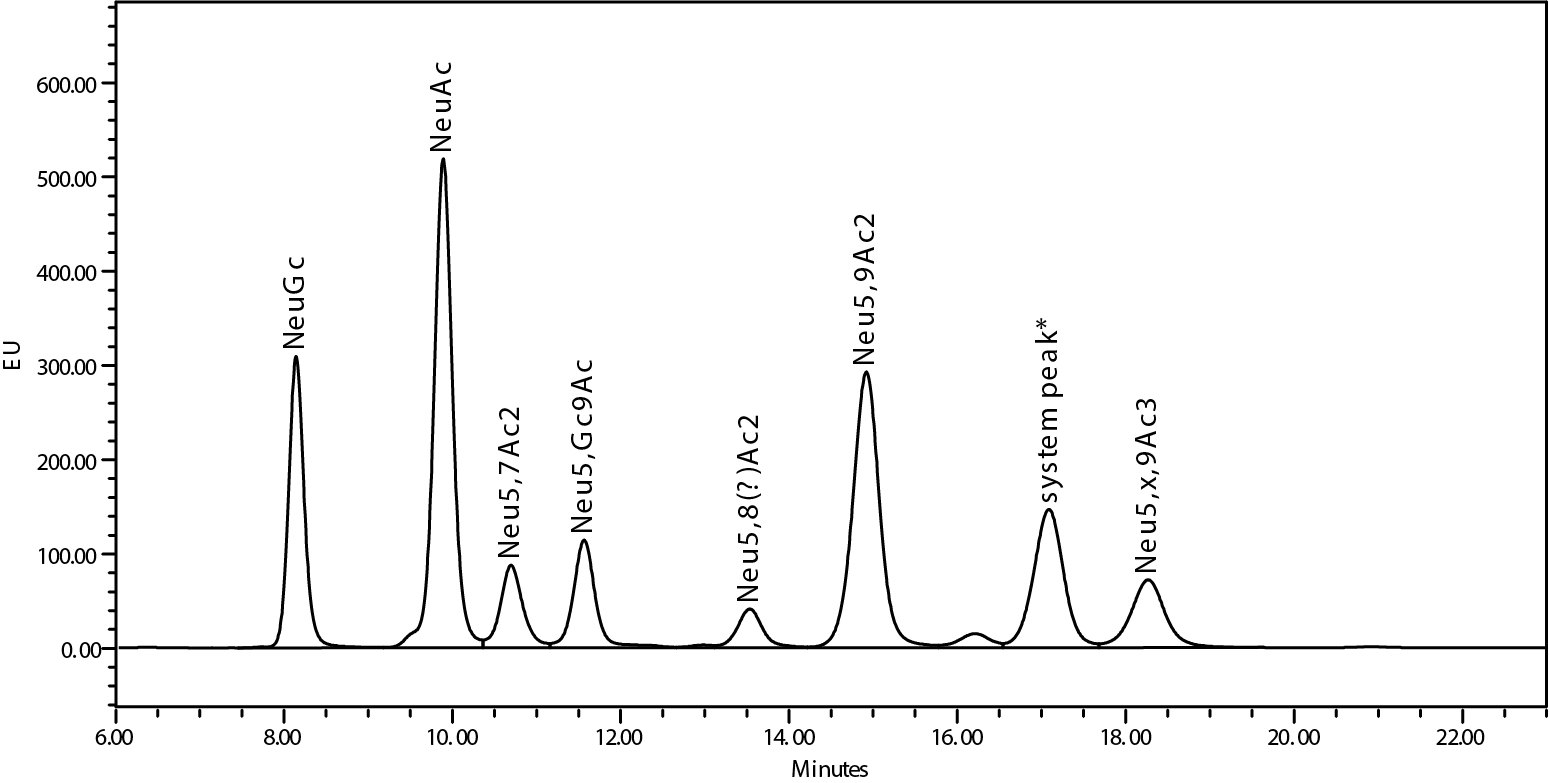

The sialic acid reference panel is a mixture of different sialic acid forms sourced from bovine submaxillary mucin. The panel contains seven sialic acids which include: Neu5Ac, Neu5Gc, Neu5,7Ac2, Neu5Gc,9Ac, Neu5,8Ac2, Neu5,9Ac2 and Neu5,x,xAc3 (where x is an unknown acetyl position). Peak assignment in the chromatogram ( Figure 1) is based on literature, standard inclusion, and NMR.

It is also supplied as a component of our LudgerTag DMB sialic acid release and labeling kit (LT-KDMB-A1).

Ludger Guides to Sialic Acid Analysis:

Sialylation Guide I: Neu5Ac and Neu5Gc Quantitation

Sialylation Guide I: Neu5Ac and Neu5Gc Quantitation

Sialylation Guide II: Highly Sialylated Glycoproteins

Sialylation Guide II: Highly Sialylated Glycoproteins

Application Note: Quantitative Sialic Acid Analysis

Application Note: Quantitative Sialic Acid Analysis

Sources: Bovine submaxillary mucin

Form: Dry. Dried by centrifugal evaporation from an aqueous solution.

Amount: 1.25 nmols

Storage: -20˚C both before and after dissolution. This product is stable for at least 5 years as supplied.

Shipping: The sialic acid reference panel can be shipped at ambient when dry. After dissolution, ship on dry ice.

Handling: Allow the unopened vial to reach ambient temperature and tap unopened on a solid surface to ensure that most of the lyophilized material is at the bottom of the vial. Gently remove the cap, add the desired volume of reconstitution medium, re-cap and mix thoroughly to bring all the oligosaccharide into solution. For maximal recovery of oligosaccharide, ensure that the cap lining is also rinsed and centrifuge the reconstituted vial briefly before use. Ensure that any glass, plasticware or solvents used are free of glycosidases and environmental carbohydrates. Minimise exposure to elevated temperatures or extremes of pH. High temperatures and low pH will cause desialylation. High pH will cause epimerisation of the reducing terminus GlcNAc.

Safety: This product is non-hazardous and has been purified from natural sources certified to be free of all hazardous material including pathogenic biological agents.

References:

Fernandes, D. Biopharmaceutical Sialylation. European Biopharmaceutical Review. Spring 2006. pp 100 -104

Bhide GP, Colley KJ. Sialylation of N-glycans: mechanism, cellular compartmentalization and function. Histochem Cell Biol. 2017 Feb;147(2):149-174. doi: 10.1007/s00418-016-1520-x. Epub 2016 Dec 14.

Anumula KR. Rapid quantitative determination of sialic acids in glycoproteins by high-performance liquid chromatography with a sensitive fluorescence detection. Analytical Biochemistry 230: pp24-30, 1995,

Figure 1: LudgerSep R1 HPLC profile of DMB labelled Sialic acid Reference Panel

Figure 1: LudgerSep R1 HPLC profile of DMB labelled Sialic acid Reference Panel