Guide to Glycosylation Analysis

Glycan Release

Liberation of glycans from glycoproteins

The first step in glycan analysis of glyconjugates such as glycoproteins and glycosphingolipids is the release of the sugars from the molecules to which they are attached.

Great care should be taken in choosing the best glycan release method from the chemical and enzymatic techniques available.

Chemical Release

Hydrazinolysis is suitable for releasing both N- and O-linked glycans from glycoproteins. It involves the incubation of the dried glycoprotein with anhydrous hydrazine followed by a straightforward workup to purify the released glycans. For success, hydrazinolysis must be carried out with absolutely pure hydrazine under strictly controlled conditions. Advantages of hydrazinolysis include its versatility with the ability to release both N- and O-linked glycans in a virtually non-selective way.

Ludger products for chemical release of glycans:

Hydrazinolysis kit (LL-HYDRAZ-A2): For release of N + O-linked glycans. Released glycans have free reducing terminii to allow fluorescent tagging by reductive amination. The release conditions can be optimized for release of N-glycans, O-glycans or both N- and O-glycans.

Orela kit (LL-ORELA-A2): For release of O-linked glycans. Released glycans have free reducing terminii to allow fluorescent tagging by reductive amination.

Enzyme (endoglycosidase) Release

Endoglycosidase release is generally a simpler method to implement than hydrazinolysis and suitable for many applications. There are a number of useful endoglycosidases, including Peptide N Glycosidase F (PNGase F), which releases most N-glycans from glycoproteins. Take care when using endoglycosidases as there are a number of conditions and substances that can lead to selective non-release of glycans. In particular, PNGaseF does not release N-glycans which have core fucose attached in the alpha1-3 position which can be found on N-glycans from plants and insects.

Ludger products for chemical release of glycans:

PNGase F (E-PNG-01 or E-PNG01-200): removes N glycans.

O-Glycosidase (E-G001): removes core 1 O glycans (Gal-β(1-3)GalNAc- alpha attached to the serine or threonine)

LudgerZyme Ceramide Glycanase kit (LZ-CER-HM-KIT): Ceramide glycanase deglycosylates a variety of glycosphingolipids by cleaving the β-glycosyl linkage.

Glycan Labeling

Tagging of glycans with fluorescent or UV-active dye labels

Release of glycans by hydrazinolysis or endoglycosidases produces glycans with a reducing terminus that can be tagged with a fluorophore or chromophore label. Most glycan labels are aromatic amines which are conjugated to the glycans by reductive amination. The procedure for this is outlined in our overview of the glycan labeling protocol.

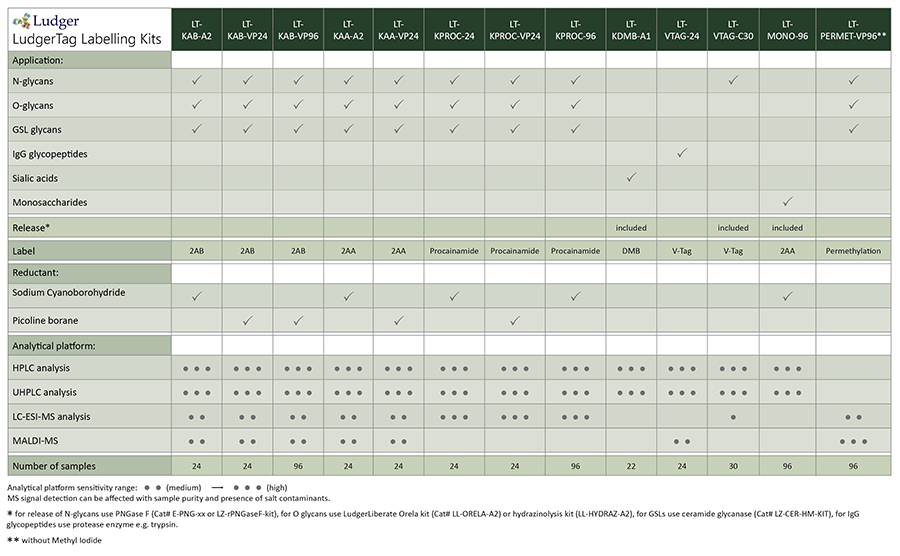

Ludger offers a range of kits for labeling glycans and glycopeptides. We have summarised the recommended applications for the LudgerTag kits in the following table:

Glycan Clean Up

Purification of glycans after procedures such as labeling and enzyme treatments

Removal of contaminating substances such as salts, proteins, peptides, or excess derivatization reagents from your glycan samples is essential for the success of many treatments and analyses. Clean up can be performed after glycan labelling or after treatment with enzymes (e.g. after glycan release or treatment with exoglycosidases)

Glycan cleanup methods that are particularly useful during glycosylation analysis include the following:

- Hydrophilic interaction

This involves application of the glycan to a hydrophilic matrix in the presence of high levels of particular organic solvents. The glycans bind to the matrix and hydrophobic non-glycan contaminants are washed off with the solvent. The purified glycans are subsequently recovered by elution with an aqueous solvent.

Examples: LudgerClean S or T1 cartridges, permethylation clean up plate, procainamide clean up plate - Electronic interaction

This uses a special resin with a very flat (on a molecular) surface of sp2 hybridized electrons. The glycans are applied to the resin in an aqueous solution and are captured. Non-organic substances such as salts are washed away and the glycans are then recovered by elution using a mixed organic-aqueous solvent. The method works very well for a wide range of glycans and allows rapid purification of the carbohydrate.

Examples: LudgerClean EB10 cartridges, EC50 cartridges - Ultrafiltration

Specialized modified polyethersulfone membrane with a molecular weight cut-off of approximately 30 kDa designed for a removal of enzymes and other protein material from glycan solution.

Examples: Post exoglycosidase clean-up spin columns and 96-well plate optimised for removal of exoglycosidase enzymes from fluorescently labelled and unlabelled glycan mixtures - Cation exchange Example: LudgerClean CEX cartridges

- Hydrophobic interaction Example: LudgerClean PBM plate

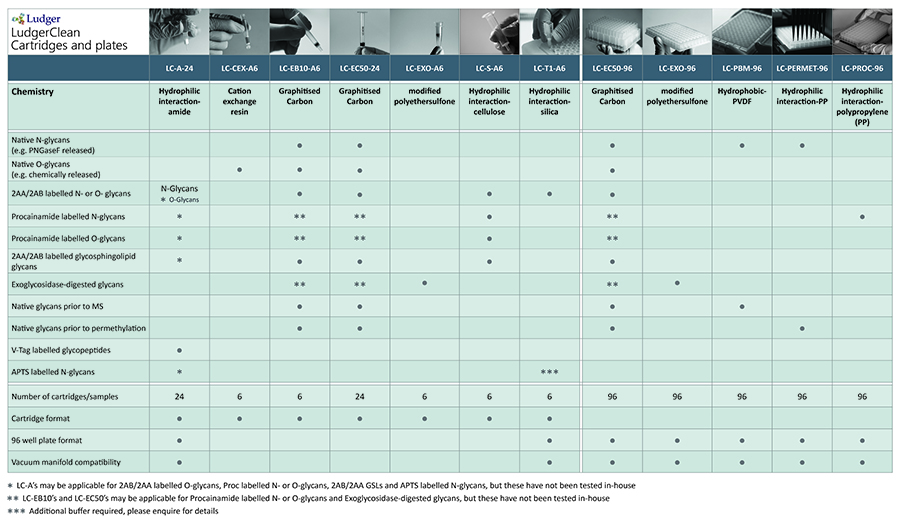

We have summarised the recommended applications for our LudgerClean products in the following table: